Engine valve guides are cylindrical metal bushes in cylinder heads, crucial for stabilizing valve stems and ensuring proper engine operation. They play a vital role in maintaining engine efficiency and longevity by guiding valve movement and dissipating heat.

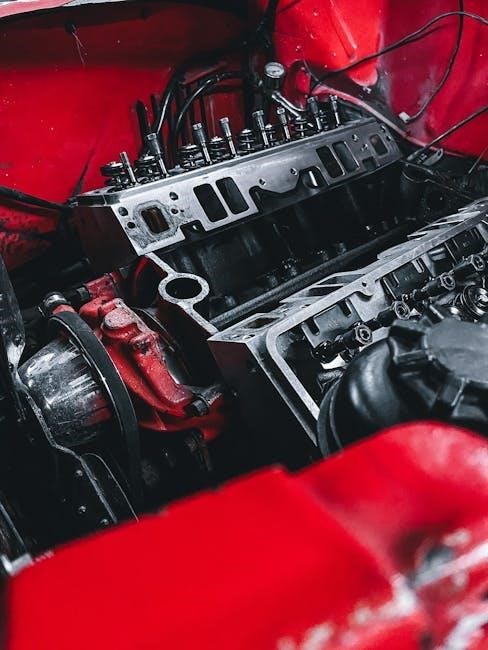

1.1 Overview of Engine Valve Guides

Engine valve guides are cylindrical bushes pressed or cast into cylinder heads, designed to support valve stems and ensure precise movement. They are integral to engine operation, providing stability and alignment for intake and exhaust valves. Typically made from durable materials like cast iron or manganese bronze, valve guides endure high thermal and mechanical stresses. Their primary role is to maintain proper valve function while dissipating heat from the combustion chamber to the cylinder head. Over time, wear can occur, especially in high-performance or turbocharged engines, necessitating regular inspection and maintenance to prevent engine damage.

1.2 Importance in Engine Performance

Valve guides are essential for optimal engine performance, ensuring precise valve operation and heat management. They stabilize valve stems, preventing misalignment and wear, which could lead to reduced power and efficiency. By facilitating proper valve sealing, they minimize oil consumption and emissions. Heat dispersion through valve guides prevents overheating, safeguarding engine components. In high-performance engines, their role is critical, as they withstand higher thermal loads. Deteriorated guides can cause poor engine performance, increased emissions, and potential damage. Thus, maintaining valve guides is vital for sustaining engine reliability, efficiency, and longevity, ensuring smooth operation across various engine types and applications.

Functions and Purposes

Engine valve guides support valve stems, ensuring proper alignment and movement. They also play a role in heat dispersion, maintaining engine efficiency and preventing overheating.

2.1 Supporting Valve Stems

Engine valve guides provide critical support to valve stems, ensuring precise alignment and smooth movement. They act as a stable base, preventing wobble and wear. The guides are designed to withstand the mechanical stress and heat generated during engine operation. Proper support is essential to maintain valve train integrity, as misalignment can lead to premature wear on components like valve seats and seals. The cylindrical shape of the guides allows for consistent contact with the valve stem, ensuring reliable performance under various engine conditions. This support system is vital for maintaining engine efficiency and longevity. Effective valve stem support is non-negotiable for optimal engine functionality.

2.2 Heat Dispersion Role

Engine valve guides play a crucial role in heat dispersion within the engine. They are designed to transfer heat generated during combustion away from the valves to the cylinder head. This prevents overheating, which could lead to valve warping or damage. High-performance materials like cast iron and manganese bronze are often used for their excellent heat-conductive properties. Proper heat management ensures optimal engine performance and longevity by maintaining consistent operating temperatures. Inadequate heat dispersion can result in reduced engine efficiency and potential damage to valve train components. Thus, the heat dispersion role of valve guides is essential for reliable engine operation.

Components and Design

Engine valve guides consist of cylindrical metal bushes, typically made from cast iron or manganese bronze, designed to be press-fit into cylinder heads for durability and efficient heat dispersion.

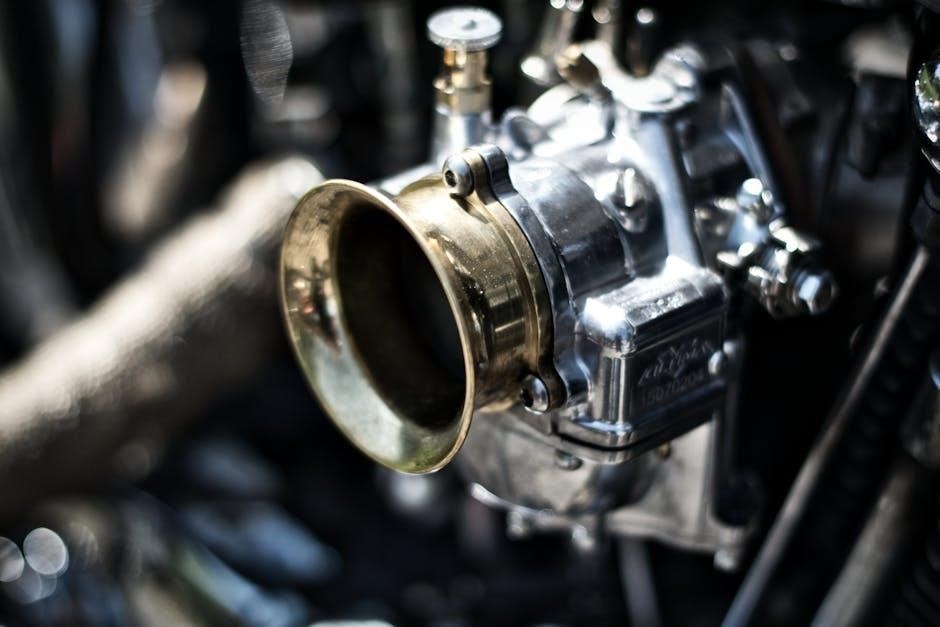

3.1 Types of Valve Guides

Valve guides are available in various types, including cast iron, manganese bronze, and integral cast designs. Cast iron guides are durable and cost-effective, while manganese bronze offers superior strength and heat resistance. Integral cast guides are built directly into the cylinder head, enhancing structural integrity. Each type is tailored to specific engine requirements, ensuring optimal performance and longevity. Proper selection depends on factors like engine type, operating conditions, and desired durability. High-performance engines often use manganese bronze for its exceptional wear resistance, while cast iron remains a popular choice for everyday applications due to its balance of cost and reliability.

3.2 Key Design Features

Valve guides are precision-engineered with a cylindrical design to ensure proper alignment and smooth operation of valve stems. They feature precise inner diameters to accommodate valve stems securely, minimizing lateral movement. Manufactured from durable materials like cast iron or manganese bronze, they offer excellent wear resistance and thermal stability. Some designs incorporate chamfers or radii for easier installation and reduced stress concentrations. Additionally, certain guides include surface treatments or coatings to enhance lubrication and heat transfer. These design elements collectively ensure consistent engine performance, reduce wear, and extend service life by maintaining optimal operating temperatures and minimizing friction between moving components.

Materials and Manufacturing

Engine valve guides are made from durable materials like cast iron and manganese bronze, ensuring strength and heat resistance. They are precision-machined using advanced CNC techniques for accuracy and reliability.

4.1 Engineered Materials Used

Engine valve guides are crafted from high-performance materials like cast iron and manganese bronze, chosen for their exceptional strength, heat resistance, and durability. Cast iron offers excellent thermal conductivity and wear resistance, making it ideal for withstanding the intense heat generated by engine combustion. Manganese bronze, on the other hand, provides superior strength and resistance to corrosion, ensuring longevity under harsh operating conditions. These materials are carefully selected to maintain precise valve alignment and thermal stability, ensuring optimal engine performance. Their engineered properties help mitigate wear and tear, making them indispensable for reliable engine operation. Quality materials are crucial for durability and efficiency.

4.2 CNC Machining Process

The CNC machining process ensures precision in manufacturing engine valve guides, delivering high accuracy and consistency. Computer-controlled machinery shapes the guides with tight tolerances, ensuring proper fitment and alignment. This advanced technique allows for intricate designs and precise dimensions, critical for optimal engine performance. CNC machining also enhances the durability and surface finish of valve guides, reducing wear and tear. By automating the production process, manufacturers achieve superior quality and reliability, meeting the demands of modern high-performance engines. This method is essential for producing valve guides that withstand extreme thermal and mechanical stresses, ensuring reliable engine operation and longevity. Precision is key to functionality.

Installation and Replacement

Proper installation of engine valve guides is crucial for engine performance. Guides are typically press-fitted into cylinder heads, requiring precise alignment. Replacement involves removing old guides and installing new ones using specialized tools, ensuring correct fitment and alignment to maintain engine integrity and performance.

5.1 Installation Techniques

Installing engine valve guides requires precision to ensure proper alignment and fitment. Specialized tools, such as pilot bushings or drivers, are used to press-fit the guides into the cylinder head. Proper alignment is crucial to prevent engine performance issues. The process involves carefully measuring and positioning the guide to ensure it is seated correctly. Incorrect installation can lead to valve misalignment, engine damage, or reduced performance. It is essential to follow manufacturer guidelines and use the appropriate tools to achieve a precise fit; A well-executed installation ensures optimal engine operation and longevity of the valve train components.

5.2 Replacement Best Practices

When replacing engine valve guides, it’s critical to follow best practices to ensure reliability and performance. Inspect the cylinder head for damage or wear, and clean it thoroughly before installation. Use precision tools to avoid damaging the new guides or surrounding components. Apply a thin layer of lubricant to the guide’s exterior for easier insertion. Properly align the guide with the valve stem to prevent misalignment. Tighten all components to the manufacturer’s specifications to avoid over-tightening, which can cause warping. Post-installation testing, such as leak-down tests, can verify the integrity of the repair. Adhering to these practices ensures optimal engine functionality and longevity.

Maintenance Tips

Regular inspection of valve guides ensures early detection of wear. Cleaning and lubricating guides prevents friction and heat buildup, maintaining optimal engine performance and longevity.

6.1 Regular Inspection

Regular inspection of engine valve guides is essential for identifying wear and tear early. Over time, valve guides can wear due to heat and friction, leading to issues like oil consumption or reduced performance. Inspectors typically look for signs of wear, such as excessive clearance between the valve stem and guide, or discoloration indicating heat damage. Using tools like dial indicators helps measure guide clearance accurately. Visual checks for scoring or abnormal patterns on the guide surface are also critical. Catching these issues early prevents costly repairs and ensures optimal engine operation. Regular inspections are a cornerstone of proactive engine maintenance.

6.2 Cleaning and Lubrication

Cleaning and lubricating engine valve guides are vital for maintaining their functionality. Use a mild solvent and a brush to remove carbon deposits and grime. After cleaning, apply a high-quality lubricant, such as silicone-based grease, to reduce friction and wear. Ensure the valve guide area is free from debris before lubrication. Regular cleaning prevents corrosion and ensures smooth valve operation. Lubrication also helps in heat dissipation, prolonging the lifespan of the valve guides. Proper maintenance prevents premature wear and enhances engine performance. Always use recommended lubricants and follow manufacturer guidelines for optimal results. Regular cleaning and lubrication are essential for engine longevity.

Common Issues and Solutions

Common issues with engine valve guides include wear, heat damage, and misalignment. Solutions involve replacing worn guides, using heat-resistant materials, and ensuring precise alignment during installation.

7.1 Diagnosing Wear and Tear

Diagnosing wear and tear on engine valve guides involves inspecting for excessive clearance, scoring, or discoloration. Technicians often use precision measuring tools to check guide tolerances. Symptoms like increased oil consumption, decreased performance, or audible noises indicate potential issues. Visual examination of the valve stem and guide for wear patterns helps confirm damage. In severe cases, worn guides can cause valve misalignment, leading to engine inefficiency or failure. Early detection through regular inspections is crucial to prevent costly repairs and ensure optimal engine performance. Proper diagnostic techniques ensure accurate assessment of valve guide condition, guiding effective maintenance or replacement strategies.

7.2 Addressing Heat Damage

Heat damage to engine valve guides can lead to warping, cracking, or excessive wear. To address this, manufacturers use materials like cast iron or manganese bronze, which offer superior heat conductivity and durability. Regular inspections help identify heat-related issues early. Maintaining proper engine cooling systems and ensuring optimal lubrication are critical to preventing heat damage. In cases of severe heat exposure, replacing the valve guides with high-performance materials is recommended. Additionally, avoiding extreme operating conditions and monitoring thermal loads can extend the lifespan of valve guides, ensuring reliable engine performance and minimizing the risk of heat-induced failures over time.

7.3 Correcting Alignment Problems

Alignment issues in engine valve guides can arise from wear, improper installation, or thermal expansion. To correct this, inspect the valve guides for any visible misalignment or uneven wear. Re-machining the cylinder head or replacing the guides may be necessary. Proper alignment ensures smooth valve operation, preventing engine performance issues. Using precision tools during installation and regular maintenance can help avoid alignment problems. Addressing these issues promptly is crucial to maintain optimal engine function and prevent further damage to components like valve stems or seats. Correct alignment ensures efficient combustion, reducing the risk of engine knock or reduced power output over time.

Factors Affecting Performance

Thermal loads and lubrication quality significantly impact valve guide performance. High thermal loads can cause wear, while insufficient lubrication leads to increased friction and potential damage.

8.1 Thermal Loads

Thermal loads significantly influence valve guide performance. High temperatures from combustion chambers can cause heat buildup, leading to guide wear and potential failure over time. Engines operating under extreme conditions, such as high-performance or turbocharged applications, are particularly susceptible. Prolonged exposure to heat can result in increased clearance between the valve stem and guide, causing oil leakage and reduced engine efficiency. Proper material selection and design features, such as enhanced cooling systems, are critical to mitigating thermal stress and ensuring longevity. Regular inspection and maintenance are essential to identify and address thermal-related issues before they escalate.

8.2 Lubrication Quality

Lubrication quality is essential for the durability and performance of engine valve guides. Proper lubrication ensures smooth operation and prevents excessive wear. High-quality engine oils reduce friction and protect against heat damage. Inadequate lubrication can lead to premature wear, increased clearance, and potential engine failure. Regular maintenance and using the correct lubricants are crucial for maintaining valve guide health and ensuring optimal engine efficiency.

Applications Across Engines

Engine valve guides are essential in various engines, including high-performance, diesel, and turbocharged engines, ensuring proper valve function and durability across diverse applications.

9.1 High-Performance Engines

Engine valve guides are critical in high-performance engines, where precision and durability are essential. In racing and high-RPM applications, guides made from materials like manganese bronze ensure minimal wear and optimal heat dispersion. They support valve stems under extreme conditions, maintaining alignment and preventing overheating. High-performance engines often require tighter tolerances and specialized coatings to handle increased thermal loads. Proper lubrication and material selection are vital to withstand the stresses of aggressive driving. Valve guides in these engines are designed to enhance performance, reliability, and longevity, making them a key component in delivering peak power and efficiency.

9.2 Diesel Engines

In diesel engines, valve guides are essential for supporting the heavier valve stems and withstanding the higher compression ratios. Diesel engines operate under greater stress due to the combustion process, making durable valve guides crucial. They must resist wear from constant piston pressure and heat generated by diesel combustion. Valve guides in diesel engines are often manufactured from robust materials like cast iron or hardened steel to ensure longevity. Proper lubrication and precise alignment are critical to maintain engine efficiency and prevent premature wear. The design of valve guides in diesel engines also considers thermal stability, ensuring reliable performance under heavy-duty conditions.

9.3 Turbocharged Engines

In turbocharged engines, valve guides are subjected to increased thermal and mechanical stress due to higher boost pressures and temperatures. These engines require valve guides made from high-strength materials to withstand the elevated heat generated by forced induction. The design of valve guides in turbocharged engines often incorporates advanced features, such as enhanced cooling pathways or specialized coatings, to improve heat dissipation and reduce wear. Proper lubrication and precise alignment are critical to maintaining performance and preventing premature failure in these high-stress environments. Durable valve guides are essential for ensuring the reliability and efficiency of turbocharged engines under demanding operating conditions.

Technological Advancements

Modern engine valve guides leverage advanced materials and coatings to enhance durability and heat resistance. Innovations in design and manufacturing improve performance, efficiency, and lifespan in demanding engine environments.

10.1 Modern Materials

Modern engine valve guides utilize advanced materials like manganese bronze and cast iron for enhanced durability. These materials offer superior heat resistance and wear resistance, critical for high-performance engines. Coatings like chromium plating further improve longevity by reducing friction and preventing corrosion. Innovations in alloy composition ensure optimal thermal conductivity, aiding heat dispersion from combustion areas to cylinder heads. Such advanced materials contribute to better engine efficiency, reduced maintenance, and extended lifespan, especially in turbocharged and diesel engines where thermal loads are higher. They are engineered to withstand extreme conditions, ensuring reliable performance and minimal wear over time.

10.2 Innovative Designs

Innovative designs in engine valve guides focus on improving durability and performance. Modern designs incorporate features like integrated cooling channels to enhance heat dispersion and reduce thermal stress. Optimized geometries minimize friction and wear, while surface treatments like diamond-like coatings further improve longevity. Some designs feature modular constructions, allowing for easier installation and replacement. These advancements cater to high-performance engines, ensuring precise valve alignment and reduced maintenance. The integration of these designs into modern engines contributes to better fuel efficiency, reduced emissions, and overall enhanced engine reliability, making them indispensable in today’s advanced automotive technologies.

Troubleshooting Guide

Common issues include excessive wear, heat damage, and misalignment. Regular inspections, timely repairs, and proper replacement techniques are essential to maintain optimal engine valve guide performance and longevity.

11.1 Identifying Failures

Identifying engine valve guide failures involves monitoring for signs like increased oil consumption, excessive valve train noise, and decreased engine performance. Inspect for wear patterns, excessive clearance, or heat damage. Use specialized tools to measure guide clearance and assess alignment issues. Regular inspections and diagnostic tests, such as compression checks, can help detect early stages of failure. Addressing these issues promptly prevents further damage to the engine. Always refer to a vehicle-specific repair manual for detailed troubleshooting steps and ensure proper tools are used for accurate diagnosis.

11.2 Repair Techniques

Repairing engine valve guides typically involves replacing worn or damaged components; This process often requires specialized tools and precision machining to ensure proper fitment. Guides are usually pressed or threaded into the cylinder head, and replacement involves carefully removing the old guide and installing a new one. CNC machining can be used to restore precise dimensions. Proper alignment and clearance are critical to prevent future issues. In some cases, oversized guides may be used if the original housing is damaged. Always follow manufacturer specifications and use high-quality materials to ensure durability and optimal engine performance. Regular maintenance can prevent the need for extensive repairs.